Session: Advanced Design/Build, Winter 2022

Builders: 12 teen builders

Materials: sheet metal (steel), cherry wood, hydraulic press brake, waterjet cut machine, clearcoat, chopsaw

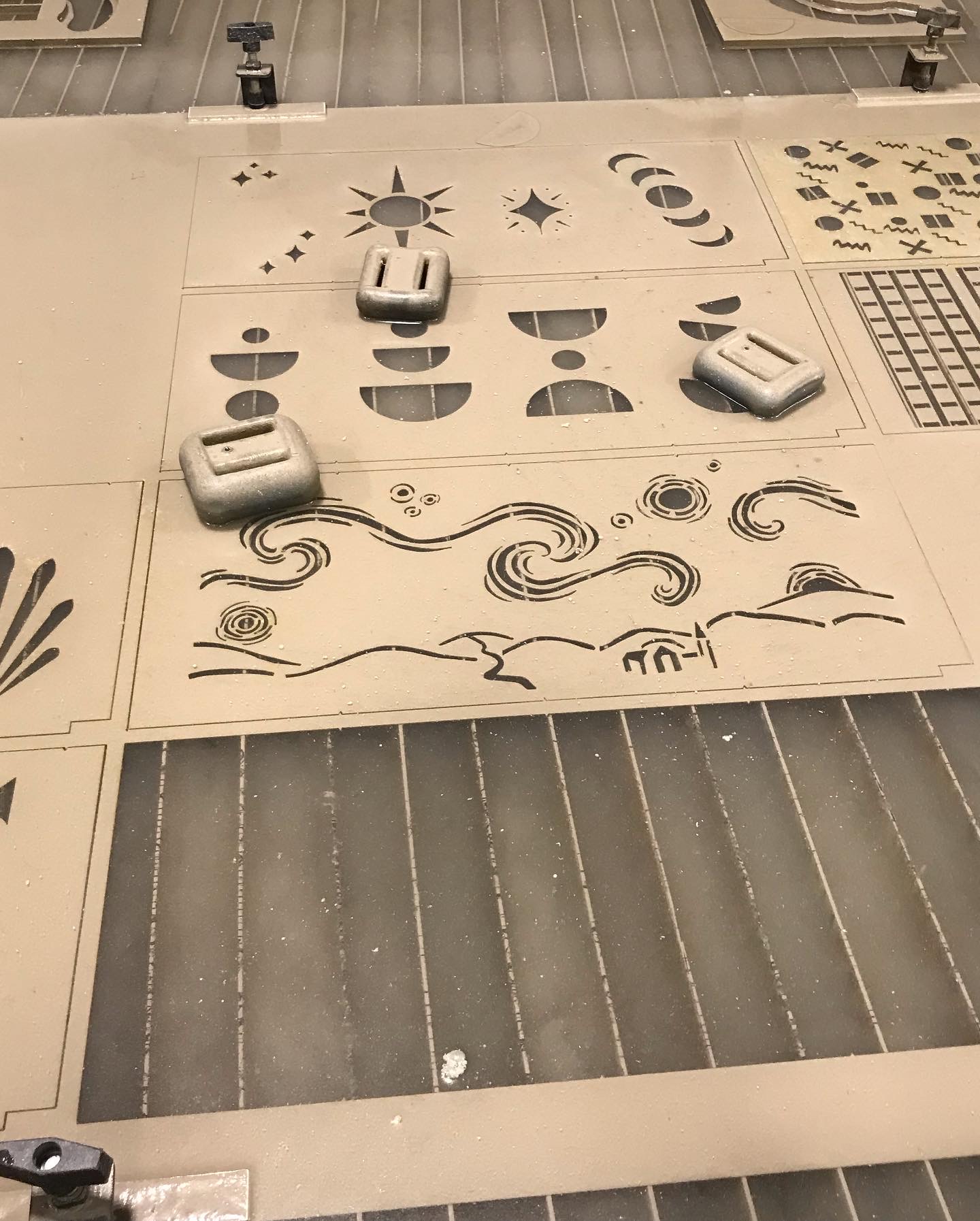

Description: In our winter session of Advanced Design/Build, our students designed and fabricated their own steel lamps. Each student used Adobe Illustrator or Rhino to draw their designs onto a template. The designs were then compiled into a one giant file that fits on 4×8 sheetmetal, and the waterjet machine cut out all of the pieces. The next step was deburring the sheetmetal and sanding the pieces. Back to the fabrication studio, our students used 2 different types of brakes to bend the sheet metal: they used the hydraulic press brake for the the first 3 90-degree turns, and for the final turn, a magnetic finger brake. In the Girls Garage workspace, our builders used a spot welder to seal the lamp. For the lumber base, they cut and sander lumber for a 6×6″ cherry base and a 1/4″ insert that the lamp was then set over. They drilled a hole through the middle for the cord, then installed the lamp socket by splitting the electrical cord and attaching the wires to the positive and negative of the bulb. Finally, they added feet to give the lamps height and glued custom acrylic cut to diffuse the light.