Session: Young Women’s Design + Building Institute and Advanced Design/Build, summer 2023

Builders: 54 high school students, support from Shelterwood’s staff

Materials: Ship-lap redwood siding, redwood 2×4 and 2×6, cedar 2×4 and tongue and groove 1×4 siding, Douglas fir 2×4 framing, ZIP system sheathing, drip-edge flashing, Rock Wool insulation, furring strips, vapor barrier, TPO roofing membrane, sauna door and window with 1/4″ tempered glass, IKI sauna heater

Description: In the summer of 2023, we embarked on our most technically ambitious project yet: an ADA-approved cedar sauna for Shelterwood Collective, a Black, Indigenous and queer-led land stewardship organization in the Cazadero forest. The sauna would be the first fixture for Shelterwood’s restorative hub, a space for their hard-working foresters and employees to relax and take care of themselves. It was also of the utmost importance that the sauna be ADA-compliant and accessible for users of all abilities, including wheelchair users.

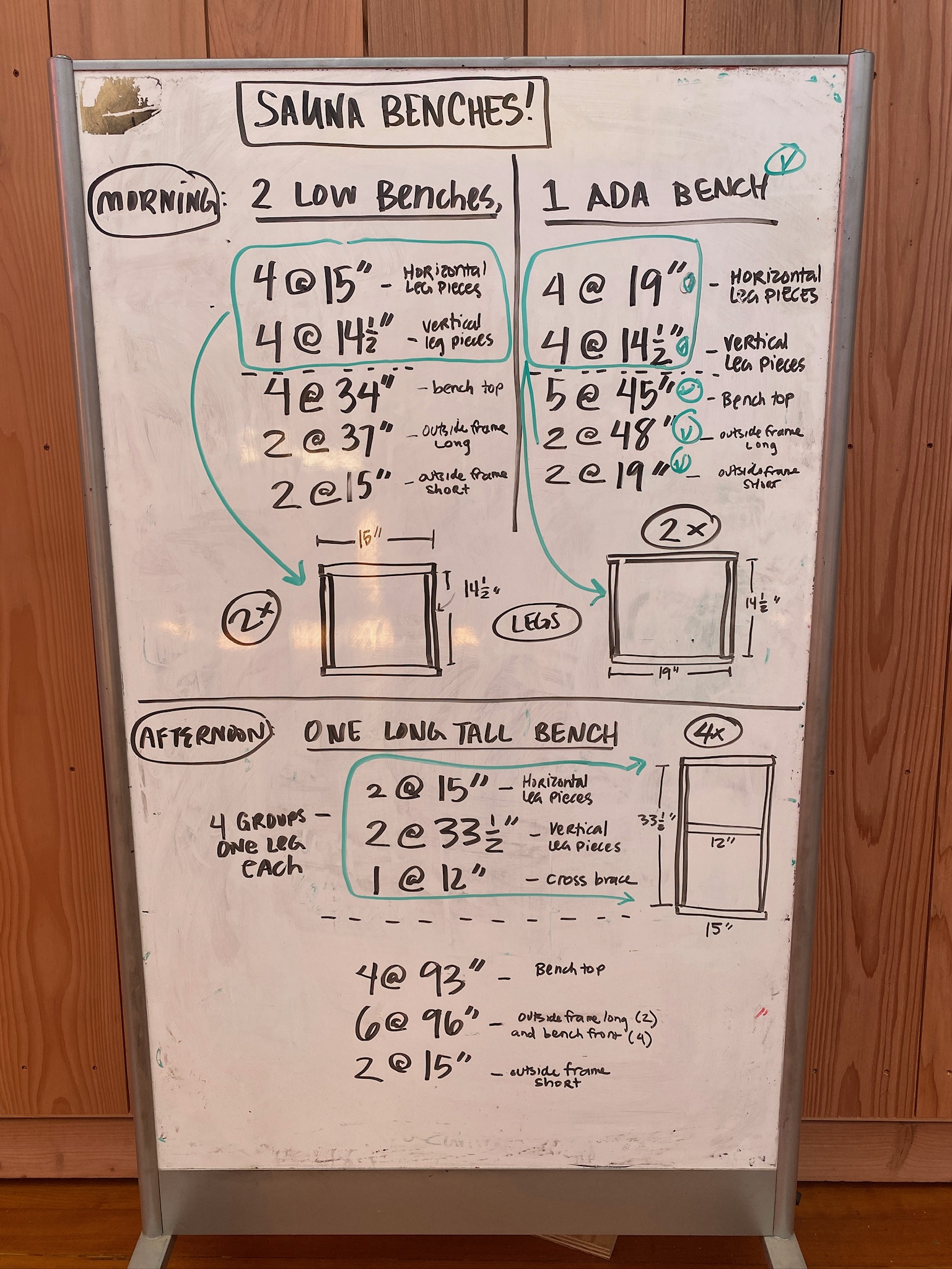

Due to the immense scale and precision of the project, it was worked on by both the Young Women’s Design + Building Institute and Advanced Design/Build cohorts for an epic cross-collaboration! Architecture instructor Tonia Sing Chi drew up the plans for the sauna (her first ever!), and Emily Pilloton-Lam and Augusta Sitney worked for months researching how to build a cedar sauna that met accessibility requirements. By the time summer programs started, we hit the ground running—nay, sprinting! Our YWDBI students framed and assembled the wall panels with a 1/16″ tolerance and installed insulation, furring strips, and interior cedar tongue and groove siding, as well as building the interior benches out of clear cedar (no knots!). Our instructors then tackled prepping the roof panels, a process that included framing and blocking, installing the vapor barrier and furring strips, and putting on the cedar panels. In total, the wall panels each had 7 layers of materials!

In late July, our Advanced Design/Build crew finished the sauna project on-site in three days, working on everything from assembling the fascia board and applying the flashing and vapor barrier to installing the tempered glass door and window. These final build days were long and the sun was hot, but spirits were high as we inched ever closer to finishing this incredible structure for this incredible organization.